“Envelope Basics: Printing” is part of an occasional series titled “Envelope Basics” that provides an in-depth look at all-things envelopes – elements, measurements, ordering tips and more*.

Printing on the envelope is your opportunity to add color, personality, and in some cases, life to your envelope. Which one you choose can depend on the kind of mailing you are doing, the size of your mailing and your budget. For example, monthly bills are frequently printed using flexography (or “flexo”) because it is typically faster and cheaper to produce, while lithographic printing is used for higher-end direct mailing.

Know the lingo. Understand the printing options for your envelope.

Flexographic Printing

Flexographic printing processes feature polymer plates that directly transfer ink to the paper like a stamp. The plates are attached to rollers and pick up ink which is then laid down on the paper in a series of small dots. The eye and brain are fooled into seeing the dots as complete, tonal images. Typically, flexographic printing is done during the envelope manufacturing process.

Flexographic Printing is frequently used for large runs of “transactional”, or billing and monthly statements, It’s frequently less expensive to set up and run. It is also popular for nonprofit appeal envelopes, or basic direct mail campaigns.

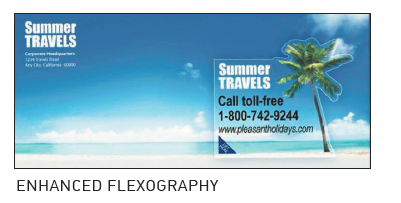

Flex Your Power with Enhanced Flexographic Printing

Enhanced flexographic allows for more elaborate and higher-quality images than with the basic > printing. Enhanced flexo print processes are typically used for 4-color process (CMYK) imagery. This style uses a central impression print cylinder for tighter print registration and digital printing plates to achieve finer screens and print resolution on calendarized papers. It’s frequently used with direct mail when images are used.

But be careful – there is no “standard” definition of enhanced flexo. Envelope manufacturers can define it differently.

Power Up with Lithography Printing

Lithography is an indirect, offset printing process that offers the highest quality. Lithographic printing is also called offset printing because ink is transferred, or “offset,” from one roller to another. It is ideal for photographs, halftones and fine screens. Offset lithography can be done on web or blank press depending on size of run.

Envelope Converting Presses: Blank and Web

There are two main types of envelope converting presses: blank fed and web fed. A blank converting press accepts die-cut paper in the shape of an unconverted envelope that is then folded and glued during the manufacturing process. A web converting press accepts continuous rolls of paper that are cut, folded and glued. It’s important to note that printing can occur during the web-fed process but not during the blank-fed process.

- Flexographic envelopes are frequently web fed, with the printing occurring during the manufacturing, or converting process. Rolls of unprinted stock are attached to envelope converting machines. Then the envelope is cut, printed and glued. Flexo printing is typically not used with blank-fed converters.

- Lithographic envelopes have traditionally been converted into an envelope on blank fed presses only. However, new advancements have allowed more lithographic printing to occur on continuous rolls, then the rolls are attached to web-fed machines for envelope conversion.

A Very Special Mailpiece

Another way to create interest in your mailpiece is to incorporate specialty print options. Integrating technology such as Augmented Reality (AR) and QR codes can deliver the benefits of combined physical and digital communication, and may qualify your mailpiece for a USPS discount. Security tints or patterned, opaque printing on the inside of the envelope for added security can be included (and even custom ordered with special patterns or your company logo). Lastly, coatings or coverings that are printed on the paper can provide a protective finish or add creativity to your mailpiece; soft-touch, iridescences and liquidized metal can up your envelope’s look (and feel in some cases).

Download Our Guide

Envelope Basics is a complete guide that details everything you need to select, measure and order the right envelope for your mail campaign.

Whether you’re a seasoned mailer or new to the mail industry, Envelope Basics includes helpful tips for your business or organization. Download your copy of Envelope Basics here.

No matter what print options you choose, a mailpiece can be an excellent boost for your integrated campaign. Contact us today to talk about how you can set your envelopes apart from the rest.

*This blog is intended for informational purposes only. Exact envelope and/or print specifications should be discussed in detail with your Sales Representative.